If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

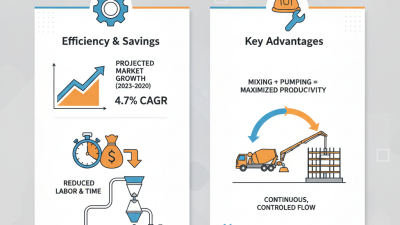

In the ever-evolving landscape of construction, efficiency and quality remain paramount. One innovative approach that has gained significant traction in recent years is on-site concrete mixing. According to a report by Grand View Research, the global ready-mix concrete market is projected to reach USD 1,180 billion by 2027, highlighting the increasing demand for flexible and cost-effective concrete solutions. On-site concrete mixing not only reduces transportation costs and logistics challenges but also enhances the quality control of the concrete being used.

Moreover, a study by the National Ready Mixed Concrete Association indicates that on-site concrete mixing can lead to a reduction in waste and increase the overall sustainability of construction projects. This method allows for the precise measurement of materials, ensuring that only what is needed is mixed, thereby minimizing surplus. As the construction industry continues to prioritize sustainable practices, on-site concrete mixing stands out as a compelling solution that not only meets the project requirements but also aligns with modern environmental standards. Embracing this technique can result in significant time savings and a smoother construction process, ultimately making it an attractive choice for various projects.

On-site concrete mixing has emerged as a transformative solution in the construction industry, significantly enhancing construction efficiency. According to a report by the National Ready Mixed Concrete Association, using on-site mixing can reduce the material waste by up to 30% compared to traditional methods. This is particularly important given that the construction sector generates approximately 600 million tons of waste annually, with concrete being a major contributor. By mixing concrete on-site, builders can precisely control the volume and composition of the mix, tailoring it to the specific requirements of the project and minimizing excess material.

Additionally, on-site concrete mixing can lead to improved project timelines. A study by the Construction Industry Institute found that timely delivery of concrete is crucial for maintaining construction schedules, and delays can cost contractors an average of $43,000 per day. By eliminating transit time and the risk of delay associated with off-site mixing, on-site mixing not only ensures fresher concrete but also enhances operational efficiency. This method allows for immediate adjustments to the mixing ratio, accommodating changes in site conditions or design requirements seamlessly as the project progresses. Overall, these benefits highlight why on-site concrete mixing is becoming the preferred choice for modern construction projects.

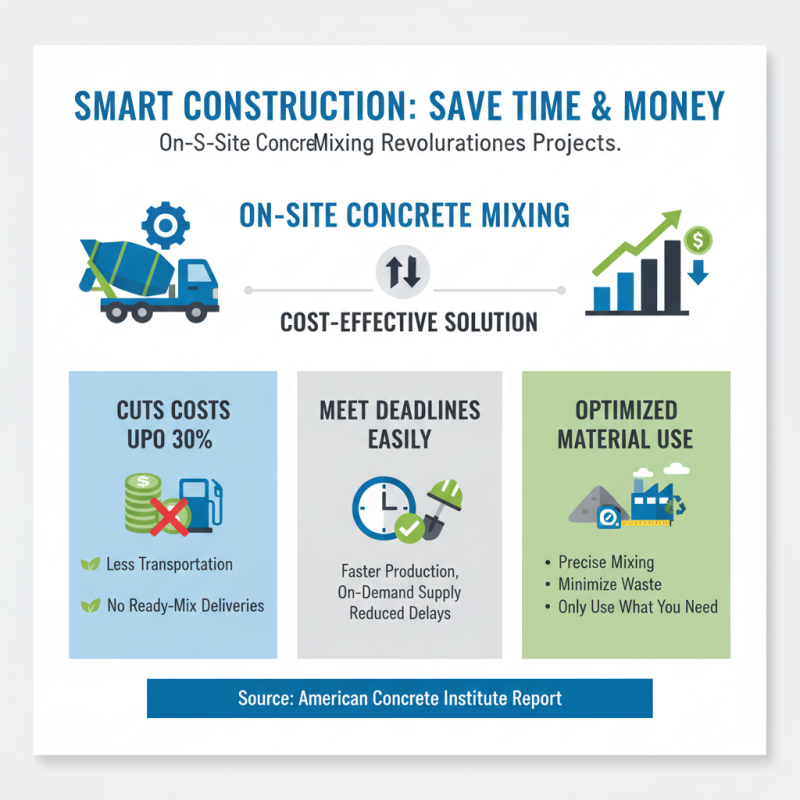

On-site concrete mixing has emerged as a cost-effective solution in the construction industry, allowing projects to meet tight deadlines while minimizing expenses. According to a report by the American Concrete Institute, on-site mixing can reduce costs by up to 30% compared to traditional methods. This significant reduction stems from decreased transportation costs and the elimination of the need for ready-mix deliveries. By producing concrete on location, construction teams can precisely manage material usage, reducing waste and ensuring that only what is needed is created.

Additionally, on-site concrete mixing enhances flexibility in scheduling, allowing for adjustments to be made in real-time based on project demands. A study by the National Ready Mixed Concrete Association indicates that projects utilizing on-site mixing experience a 20% increase in productivity due to the immediate availability of fresh concrete. This not only accelerates the construction timeline but also lowers labor costs as teams can work more efficiently without waiting for materials to arrive. Overall, the integration of on-site concrete mixing is a strategic choice for project managers aiming to optimize budget and resources.

On-site concrete mixing offers significant advantages in terms of quality control that can greatly enhance the outcomes of any construction project. When concrete is mixed directly at the job site, it allows for immediate adjustments to be made based on real-time conditions. Factors such as weather, temperature, and humidity can significantly affect the curing process and setting time of concrete. Mixing on-site enables contractors to tailor the concrete mix formula precisely to the environmental conditions, ensuring optimal performance and durability.

Additionally, on-site mixing minimizes the risk of material degradation that can occur during transportation. Ready-mixed concrete may need to travel long distances, during which time it can lose its workability. By mixing the concrete on-site, contractors can ensure that the concrete remains fresh and maintains its intended properties until the moment it is poured. This results in a superior product that meets the specific requirements of the project, reducing the likelihood of cracking, shrinkage, or other issues associated with inferior mixes. In essence, the ability to oversee the entire mixing process directly contributes to a higher standard of quality for the construction being undertaken.

On-site concrete mixing is increasingly recognized for its environmental advantages, which make it a superior choice for construction projects. According to a report by the National Ready Mixed Concrete Association, approximately 10% of the carbon footprint in the construction sector comes from transporting pre-mixed concrete. By mixing concrete on-site, projects can significantly reduce the distance materials need to travel, which directly decreases greenhouse gas emissions associated with transportation. This not only conserves energy but also minimizes the overall environmental impact of construction activities.

Furthermore, on-site mixing allows for precise control over material quantities, reducing waste. A study from the Concrete Sustainability Hub at MIT found that optimizing mixing processes can lead to a 20-30% reduction in cement usage, a key contributor to carbon emissions in concrete production. This tailoring of concrete mixtures to meet specific project needs not only ensures that excess materials are not discarded but also enhances the properties of the concrete used. By embracing on-site concrete mixing, construction projects can align with sustainable practices while maintaining efficiency and performance, making it a compelling option for environmentally conscious builders.

On-site concrete mixing offers unparalleled flexibility and customization that traditional methods simply cannot match. By mixing concrete directly at the construction site, project managers can tailor the concrete's properties to meet specific project requirements. This adaptability is especially beneficial when dealing with varied weather conditions, local materials, or unique design specifications that may not be achievable with pre-mixed concrete from a batch plant.

Moreover, on-site mixing allows for immediate adjustments in the concrete’s composition. If the construction team finds that the initially planned mix doesn't deliver the desired strength or workability, they can modify the mix on-the-fly. This capability not only enhances the quality of the concrete but also minimizes waste, as any leftover materials can be reused or repurposed for later stages of the project. In essence, the process fosters a more responsive approach to construction, ensuring that deviations from the initial plan can be addressed promptly without significant delays or additional costs.

| Dimension | Description | Benefits |

|---|---|---|

| Customization Options | Ability to adjust concrete mix according to specific project requirements. | Tailored mixtures for varying strength, workability, and curing needs. |

| Quality Control | Immediate oversight and adjustments during mixing process. | Higher consistency and reduced likelihood of defects. |

| Logistics and Time Efficiency | Elimination of transportation time and issues associated with off-site mixing. | Faster project execution and reduced delays. |

| Resource Optimization | Using only the necessary amount of materials for the project. | Minimized waste and cost-effectiveness. |

| Adaptability to Weather Conditions | Ability to mix concrete based on real-time weather forecasts. | Enhanced performance characteristics of concrete under specific environmental conditions. |