If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

A mobile concrete mixer truck is an innovative piece of equipment that revolutionizes the construction industry by allowing for the efficient mixing and transportation of concrete. Unlike traditional concrete delivery methods, which can often result in delays and inconsistencies, the mobile concrete mixer truck combines the mixing and delivery processes into one streamlined operation. This not only enhances productivity on job sites but also ensures that the concrete arrives fresh and ready to use.

Understanding how a mobile concrete mixer truck works is essential for construction professionals looking to optimize their workflow. These trucks are equipped with advanced mixing technology that allows for on-the-spot production of concrete, giving operators greater control over the consistency and quality of the mix. By exploring the key components and operational techniques of mobile concrete mixer trucks, industry stakeholders can gain valuable insights into their potential advantages, such as reduced transportation costs and minimized waste.

In this discussion, we will delve into the fundamental aspects of mobile concrete mixer trucks, examining their design, functionality, and the impact they have on modern construction practices. By appreciating the versatility and efficiency of these vehicles, contractors can significantly improve their project execution and overall results.

A mobile concrete mixer truck is an innovative transportation solution that combines concrete mixing and delivery into a single unit. This type of truck is equipped with a rotating drum that mixes raw materials like cement, sand, gravel, and water while on the move, allowing for fresh concrete to be delivered directly to construction sites. According to a report by the Global Mobile Concrete Mixer Market, the demand for mobile concrete mixer trucks has surged due to rapid urbanization and increased infrastructure development projects worldwide, with an expected growth rate of over 5% annually through 2025.

The operational efficiency of mobile concrete mixer trucks significantly reduces downtime and labor costs on job sites. Unlike traditional concrete delivery methods, which rely on fixed batch plants, mobile mixers can produce concrete on-site and adjust mix quantities as needed. This flexibility addresses the issue of waste due to overproduction and ensures that construction projects receive the exact amount of concrete required. Moreover, the ability to mix concrete on demand enhances the quality and consistency of the mix, addressing concerns related to material segregation and setting time, which are crucial for the integrity of construction works.

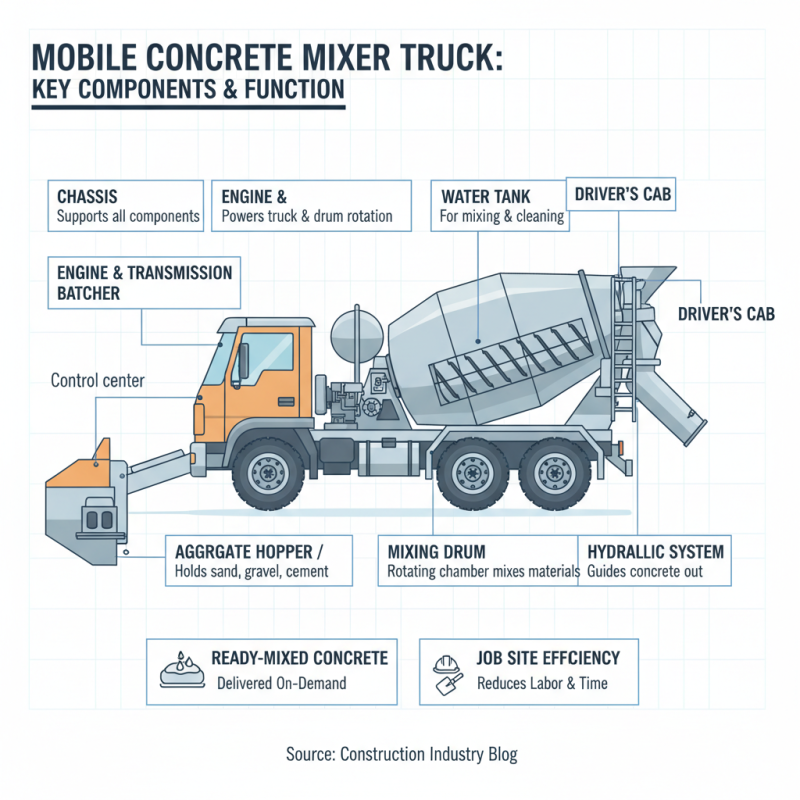

A mobile concrete mixer truck is an essential piece of equipment in the construction industry, designed to deliver ready-mixed concrete to job sites efficiently. Understanding its key components is crucial for anyone involved in construction or concrete delivery.

The heart of a mobile concrete mixer truck is its mixing drum, where the raw materials—cement, water, and aggregates—are mixed together. This drum is mounted on a chassis, making the truck mobile. Additionally, there are hydraulic systems that power the drum's rotation, allowing for continuous mixing as the truck travels. The discharge system is vital as well; it enables precise control over the release of concrete at the project site.

**Tips:** When operating a mobile concrete mixer truck, ensure that the mixing drum is properly calibrated to achieve the desired concrete consistency. Regular maintenance of hydraulic systems is crucial for safe operation and longevity of the truck. Furthermore, always adhere to safety regulations to protect the crew and the public during concrete delivery. Keeping the truck clean and free of hardened concrete can also enhance its performance and efficiency.

A mobile concrete mixer truck is a specialized vehicle designed to combine and deliver concrete to construction sites. The core function of this truck lies in its ability to mix ingredients—cement, water, and aggregates—on-site, ensuring that the concrete is freshly made and can be customized as needed for various projects. The mixing process starts once the truck arrives at the location; the driver activates the mixer to blend the materials efficiently. This functionality is particularly beneficial for large projects that demand precision in the concrete's composition.

One significant aspect of how a mobile concrete mixer truck functions is its hydraulic system, which powers the mixing drum's rotation. The truck can adjust the speed and position of the drum, providing versatility in mixing and discharging the concrete. Additionally, modern mobile mixers are often equipped with advanced technology, such as computerized controls, which enable operators to monitor the mixing process and mix design closely. This precision is crucial for achieving high-quality concrete that meets specific engineering standards.

Tips: When using a mobile concrete mixer truck, ensure that the site is prepared and accessible to avoid delays. It's also wise to evaluate the required concrete mix design ahead of time. Properly coordinating the delivery and mixing schedule can enhance efficiency and yield better results for construction projects.

Mobile concrete mixer trucks have become an essential tool in the construction industry, offering numerous advantages that enhance efficiency and quality. One of the primary benefits of using mobile concrete mixer trucks is their ability to produce fresh, high-quality concrete on-site. This ensures that the concrete mix is consistent and meets project specifications, reducing the risks of delays or issues caused by using pre-mixed concrete transported over long distances. According to a report by the American Concrete Institute, on-site mixing can improve compressive strength by up to 20%, making it a crucial factor for construction durability.

Another advantage of mobile concrete mixer trucks is their versatility. They can easily navigate construction sites, including tight spaces where traditional stationary mixers would not be feasible. This flexibility allows construction teams to control schedules better, streamline operations, and reduce downtime. Industry insights suggest that the use of mobile mixers can cut project completion times by an average of 15% due to their ability to deliver concrete precisely when and where it is needed.

Tips: Investing in maintenance for your mobile concrete mixer truck can greatly extend its lifespan and ensure optimal performance. Regularly check the mixer drum for wear and tear, and keep the hydraulic systems well-lubricated to avoid costly repairs. Additionally, always ensure that the concrete is mixed to specifications on-site to maximize quality and minimize waste.

Mobile concrete mixer trucks play a crucial role in various construction applications, offering significant advantages in both efficiency and flexibility. These specialized vehicles are designed to transport and mix concrete on-site, which is particularly beneficial for projects that require precise measurements and immediate use of concrete. This capability allows construction teams to respond quickly to changing project demands, ensuring that the concrete is freshly mixed and at its optimal consistency when it arrives at the job site.

In residential construction, mobile concrete mixer trucks are valuable for pouring foundations, driveways, and patios. The ability to mix concrete on-site eliminates delays often associated with waiting for deliveries from batch plants. Additionally, this method reduces the risk of waste and improves the overall quality of the concrete since it can be mixed in small batches tailored to specific project needs. Moreover, in larger-scale construction projects, such as infrastructure development or commercial buildings, these trucks facilitate the efficient pouring of large volumes of concrete, maintaining a steady supply that aligns with the construction schedule. By utilizing mobile concrete mixers, contractors can enhance productivity while ensuring that the concrete meets the necessary specifications for strength and durability.

| Feature | Description |

|---|---|

| Type | Mobile Concrete Mixer Truck |

| Mixing Capacity | 3 to 12 cubic meters |

| Power Source | Diesel or Electric |

| Features | Self-loading, Portable, Easy operation |

| Typical Applications | Building foundations, Road construction, Bridge repairs |

| Advantages | Flexibility, Reduced transportation costs, On-site mixing |

| Disadvantages | Limited capacity, Maintenance requirements |