If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

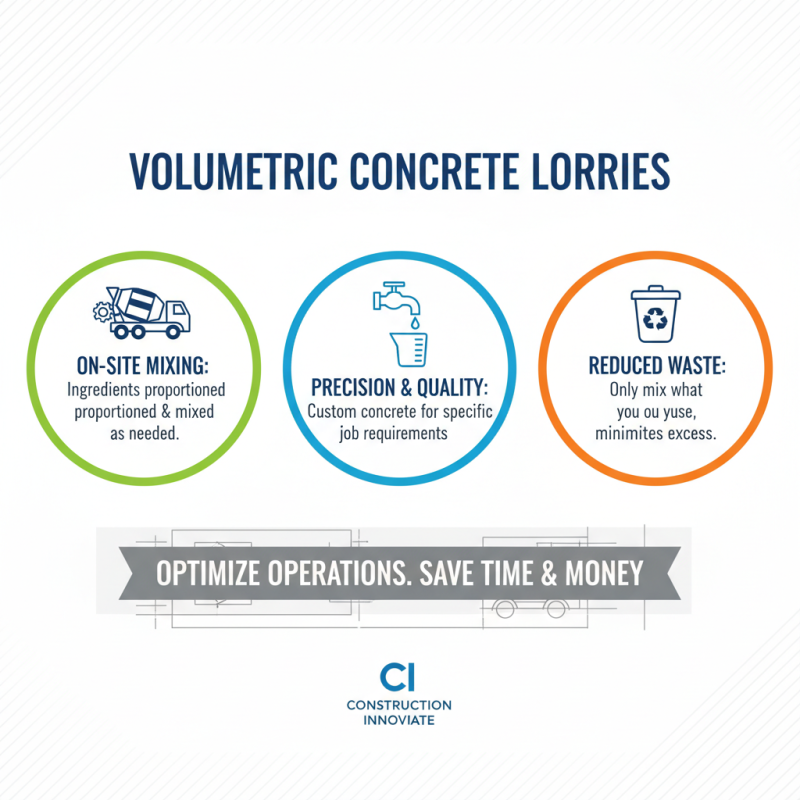

In the ever-evolving construction industry, the use of a volumetric concrete lorry is becoming increasingly prevalent due to its flexibility and efficiency. According to a recent report by the National Ready Mixed Concrete Association, the volumetric concrete market is projected to grow by 8% annually, reflecting a significant shift towards on-demand concrete delivery systems. This shift can be attributed to the lorry's ability to mix concrete on-site, reducing waste and ensuring that the material used is fresh and tailored to project specifications.

Expert in concrete logistics, Dr. Emily Harris, notes, "The volumetric concrete lorry revolutionizes the way we approach concrete mixing, allowing for precise control over material quantities and reducing the potential for excess." With the rising demand for more efficient practices in construction, understanding how to utilize a volumetric concrete lorry effectively has become essential for contractors looking to optimize their operations. This introductory guide aims to provide ten critical tips to help professionals maximize the benefits of using this innovative equipment, enhancing productivity and ensuring quality in every project.

Volumetric concrete lorries represent a significant innovation in the construction industry, providing a flexible and efficient solution for delivering concrete. These specialized vehicles can mix concrete on-site, allowing for precise control over the ingredients and ensuring that the concrete meets specific requirements. Understanding the basics of volumetric concrete lorries is crucial for construction professionals looking to optimize their operations and reduce waste.

The core function of a volumetric concrete lorry lies in its ability to store the raw materials—cement, sand, gravel, and water—separately, which means that concrete can be mixed in exact quantities as needed, avoiding over-ordering and minimizing excess. This not only saves time but also cuts costs associated with disposal of leftover concrete. Moreover, these lorries are equipped with advanced hydraulic systems that ensure a smooth mix, thereby enhancing the quality of the finished product. Additionally, operators should be mindful of calibration and maintenance practices to ensure that the lorry consistently delivers the right mix every time.

Navigating the operational aspects of volumetric concrete lorries requires a solid understanding of their functionality. Familiarity with the controls and features of the lorry can significantly improve the efficiency of the concrete delivery process. Training for operators is essential to maximize the benefits of using volumetric concrete, as they need to be adept at adjusting the mix on-site according to project specifications. By grasping the foundational elements of these versatile vehicles, construction teams can enhance project outcomes and streamline their workflow.

Volumetric concrete lorries are a game-changer in the construction industry, offering unmatched flexibility and efficiency. These vehicles allow on-site mixing of concrete, providing fresh material tailored to specific requirements. According to the National Ready Mixed Concrete Association, volumetric mixers can reduce waste significantly, with estimates showing a potential 30% decrease in excess concrete compared to traditional methods. This not only conserves resources but also minimizes environmental impact, aligning with sustainability goals that are increasingly prioritized in the industry.

One key advantage of using a volumetric concrete lorry is the precise control it offers over the mix design. Operators can adjust the ratios of ingredients on the fly, accommodating various project needs without delay. For instance, ensuring the correct slump for pouring in challenging conditions can lead to smoother operations and better end results. When utilizing volumetric lorries, it's essential to regularly calibrate your machinery to maintain accuracy in mixing. This not only guarantees quality but also enhances overall productivity on-site.

Furthermore, volumetric trucks can operate in restricted environments where traditional mixing setups might face challenges. This capability places contractors in a stronger position to meet tight deadlines and demanding project specifications. To maximize the benefits these vehicles provide, always plan logistics meticulously. Conducting pre-pour meetings to discuss timelines and specific needs can streamline the process and enhance communication among team members. By embracing these strategies, construction professionals can leverage volumetric concrete lorries to their fullest potential, driving project success and efficiency.

Before operating a volumetric concrete lorry, thorough preparation is key to ensuring a smooth and efficient process. Begin by conducting a comprehensive inspection of the vehicle, checking essential components such as the drum, conveyor system, and controls. Look for any signs of wear or damage that could lead to operational issues. Additionally, ensure that all safety equipment is in place and functioning properly, including any required personal protective gear for workers on-site.

Tip: Familiarize yourself with the lorry's operating manual prior to any task. Understanding the specific functions and features of the vehicle can make a significant difference in performance during a job. This knowledge will enable you to troubleshoot minor issues before they escalate, keeping the project on track.

Next, assess the delivery site for accessibility and space. Clear any obstacles to ensure the lorry can maneuver easily and reach the designated pouring area. It's also beneficial to coordinate with your team to establish a clear communication plan, which can streamline the process and monitor the concrete discharge effectively.

Tip: Always plan for the specific mix requirements of the project. Preparing the precise ratios in advance can save time and prevent mix-related delays once the lorry is on-site, allowing for a more efficient application of the concrete.

| Tip Number | Tip Description | Preparation Step |

|---|---|---|

| 1 | Check the Equipment | Inspect all components before operation. |

| 2 | Review Safety Protocols | Ensure all team members understand safety measures. |

| 3 | Calibrate the Mixer | Ensure the mixer is calibrated for accurate measurements. |

| 4 | Prepare the Site | Clear the area and establish a safe working environment. |

| 5 | Gather Necessary Materials | Ensure all materials required for mixing are available. |

| 6 | Plan the Delivery | Schedule the delivery time to meet project deadlines. |

| 7 | Communicate with the Team | Coordinate effectively with all team members. |

| 8 | Perform a Dry Run | Practice the procedure before actual mixing starts. |

| 9 | Maintain Cleanliness | Keep the work area and equipment clean and organized. |

| 10 | Conduct Post-Operation Review | Evaluate the operation for improvement in future use. |

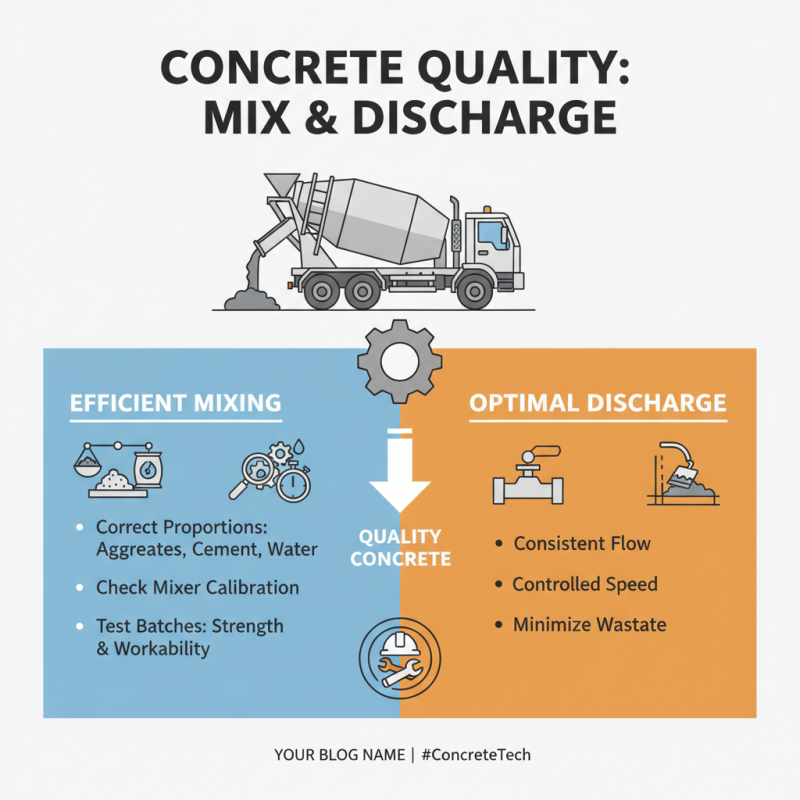

When utilizing a volumetric concrete lorry, effective mixing and discharging techniques are crucial to ensure the quality and consistency of the concrete. First and foremost, it is essential to ensure that the materials, including aggregates, cement, and water, are loaded in the correct proportions. This not only leads to a well-mixed product but also minimizes wastage, making the operation more efficient. Regularly checking the calibration of the mixer and conducting test batches can help maintain the accuracy of the mix design and ensure that the desired concrete strength and workability are achieved.

Once the concrete is mixed, the discharging process requires careful attention. Operators should aim to initiate the discharge at the site with a clear plan for where the concrete will go. It's crucial to employ proper techniques to prevent segregation, such as maintaining a consistent pouring height and using appropriate tools to spread the concrete evenly. Additionally, considering the surrounding environment is important; weather conditions can affect setting times, and adjustments in the mix might be necessary if extreme temperatures are present. By adhering to these best practices, operators can maximize the effectiveness of the volumetric concrete lorry and deliver a high-quality product that meets project specifications.

When using a volumetric concrete lorry, safety should always be a top priority. Operators must ensure that they are fully trained and familiar with the equipment before commencing work. This includes understanding the controls, load capacities, and the specific hazards associated with the mixing and pouring of concrete.

Prior to operation, it is essential to conduct a thorough inspection of the lorry, checking for any signs of wear or malfunction. This proactive approach can help to prevent accidents on the job site.

Moreover, proper site preparation is critical. The area where the concrete is to be poured must be clear of obstacles, and adequate space should be provided for the lorry to maneuver safely. Always use appropriate personal protective equipment (PPE), such as hard hats, gloves, and steel-toed boots.

It's also important to maintain communication with other team members to ensure that everyone is aware of the lorry's movements and the ongoing operations.

Adhering to these safety considerations can significantly reduce the risk of accidents and injuries while working with a volumetric concrete lorry.