If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

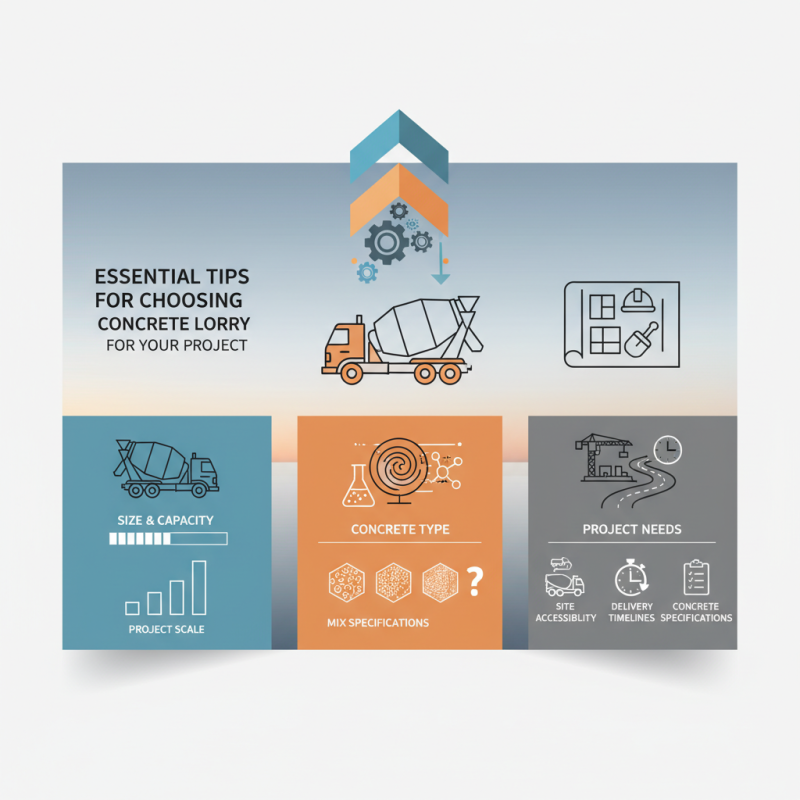

When embarking on a construction project that requires concrete, selecting the right concrete lorry is a critical decision that can significantly impact the efficiency and success of your work. Concrete lorries, or mixer trucks, are essential for transporting ready-mixed concrete directly from the production facility to the construction site. Understanding the various factors that influence your choice can save you time, money, and hassle down the line.

There are several aspects to consider when choosing the appropriate concrete lorry for your project. The size and capacity of the lorry should align with the scale of your project, ensuring that it can deliver the required volume of concrete without delays. Additionally, the type of concrete needed for your specific application should be matched with a lorry that is designed to handle that particular mix, guaranteeing the integrity and quality of the final product.

Ultimately, making an informed decision about the right concrete lorry involves evaluating your project's unique needs, including site accessibility, delivery timelines, and concrete specifications. By taking the time to consider these essential factors, you can ensure a smoother workflow and optimal results in your construction endeavors.

When selecting the right concrete lorry for your project, it's essential to understand the various types available to ensure you choose the most suitable one. Generally, concrete lorries fall into a few main categories: transit mixers, volumetric mixers, and concrete pump trucks. Each type serves a unique purpose and is designed to cater to specific project needs.

Transit mixers, commonly recognized for their rotating drum, are ideal for delivering ready-mixed concrete directly to the job site. They keep the concrete agitated during transportation, ensuring optimal consistency and preventing premature setting. On the other hand, volumetric mixers are distinct as they mix concrete on-site. This flexibility allows for adjustments in volume and mix proportions depending on the project's requirements, making them perfect for smaller, bespoke jobs where precise quantities are necessary.

Concrete pump trucks combine the capabilities of concrete lorries with the efficiency of pumps, enabling the placement of concrete in hard-to-reach areas. This type of lorry is particularly beneficial for high-rise buildings or sites with challenging terrain. By understanding these different types of concrete lorries, you can make an informed decision that aligns with your project specifications and logistical considerations.

This chart illustrates the various types of concrete lorries and their respective capacities in cubic meters (m³). Understanding these different types can help you choose the right lorry for your construction project based on your specific concrete needs.

When selecting a concrete lorry for your project, several key factors must be considered to ensure optimal performance and efficiency. First, assess the capacity of the lorry based on your specific project needs. Concrete lorries typically vary in size, with capacities ranging from small trucks suitable for residential use to larger vehicles designed for commercial projects. Determine the volume of concrete required, factoring in the dimensions of your project site to avoid unnecessary delays.

Another important aspect is the type of concrete lorry. Options include standard trucks and those equipped with advanced features like integrated pumps or chutes, which can help with precision placement. Evaluate the terrain of your project site as well—if the site is challenging to access, a lorry with off-road capabilities may be essential.

Tips to keep in mind include checking the maintenance history of the lorry to ensure reliability, and inquiring about the driver’s experience with similar projects. It’s also wise to confirm availability for your project timeline to avoid any last-minute issues. By paying attention to these factors, you can make a more informed decision that aligns with your project’s requirements.

| Factor | Description | Importance |

|---|---|---|

| Capacity | Ensure the lorry can hold enough concrete for your project needs. | High |

| Maneuverability | Consider how easy it is to navigate the lorry on your site. | Medium |

| Delivery Distance | Check if the lorry can efficiently travel from the plant to your site. | High |

| Mixing Technology | Evaluate the mixing technology to ensure quality concrete. | High |

| Cost | Analyze the cost in relation to quality and service provided. | High |

| Safety Features | Ensure lorry has necessary safety mechanisms for operation. | Very High |

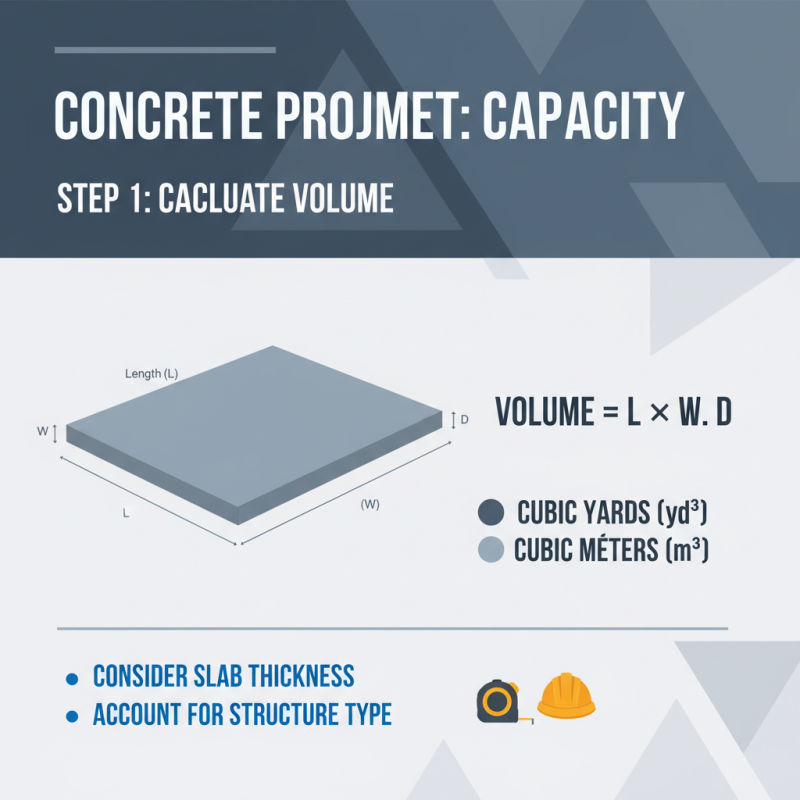

When evaluating the capacity requirements for your concrete project, the first step is to accurately determine the amount of concrete you will need. This is typically expressed in cubic yards or cubic meters, depending on your region. To calculate this, measure the dimensions of the area to be filled—length, width, and depth—using a tape measure. Multiplying these dimensions together will give you the total volume. Consider any additional factors such as the thickness of the slab or the type of structure you are building, which can impact the overall quantity required.

Once you have your volume determined, it’s important to assess the capacity of different concrete lorries. Concrete trucks come in various sizes, typically ranging from 6 to 10 cubic yards for small projects, and larger trucks can accommodate up to 12 or 14 cubic yards. If your project requires a significant amount of concrete, opting for a larger lorry can help minimize wait times and reduce the number of trips needed for delivery. Additionally, ensure you account for potential spillage or over-excavation, as ordering a little extra concrete (generally around 10% more) can help avoid delays that might arise from needing additional deliveries. Properly aligning your project's capacity with the right concrete lorry will lead to a smoother execution and successful completion.

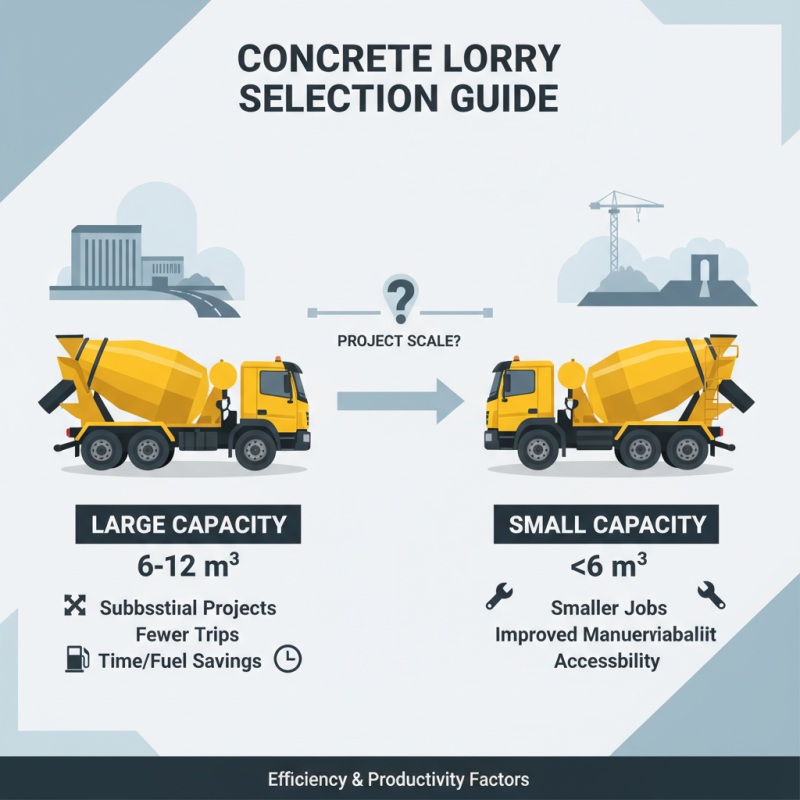

When selecting the right concrete lorry for your project, it's crucial to assess the specific features and specifications that affect both efficiency and productivity. First, consider the capacity of the concrete lorry, which typically ranges from 6 to 12 cubic meters. A larger capacity lorry can reduce the number of trips required for substantial projects, ultimately saving time and fuel costs. However, for smaller jobs, a lorry that is too large may not be maneuverable enough, leading to potential accessibility issues.

Another important aspect to evaluate is the drum design and mixing technology of the concrete lorry. A well-designed mixing drum ensures uniformity and consistent delivery of concrete, minimizing the risk of segregation. Features like rotating speed control and hydraulic systems contribute to the overall effectiveness of the lorry, allowing for better mixing and easier discharge of concrete. Additionally, look for lorries equipped with GPS tracking or real-time monitoring systems, as these can enhance logistics and delivery accuracy, making your project more manageable and efficient.

When operating concrete lorries, safety and efficiency are paramount to the success of any construction project. First and foremost, effective training for the operators is essential. Each driver should be thoroughly familiar with the lorry’s controls, loading procedures, and the specifics of concrete handling. Regular training sessions can help reinforce protocols and introduce best practices, ensuring that operators are prepared to handle any situation that may arise on-site.

Additionally, planning the logistics of the concrete delivery is crucial for maintaining efficiency. Operators should coordinate closely with site managers to determine the optimal timing for concrete deliveries, taking into account factors such as the progress of the project and weather conditions. Proper scheduling reduces waiting times and minimizes the risk of material hardening before it is poured. Furthermore, maintaining the lorry in good working condition through routine inspections and timely repairs can ensure that operations run smoothly, avoiding costly delays caused by equipment failures.

By prioritizing safe operation and thorough preparation, teams can help ensure that concrete lorries contribute positively to project timelines and outcomes.