If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

When embarking on a construction project, selecting the right equipment is crucial for success. One of the most important tools in any masonry or concrete work is the cement mixer machine. This equipment not only ensures consistent mixing of materials but also greatly enhances the efficiency and quality of the final outcome. However, with various types and models available in the market, choosing the right cement mixer machine can be a daunting task.

This guide aims to provide essential tips that will aid in making an informed decision when selecting a cement mixer machine for your project. Whether you're a seasoned contractor or a DIY enthusiast, understanding the features and capabilities of different mixers will empower you to choose the best option for your specific needs. By considering factors such as capacity, portability, and power source, you can ensure that your cement mixer machine is well-suited for the demands of your project. Let's explore the key aspects that will help you in selecting the perfect mixer for a successful construction endeavor.

When selecting the right cement mixer machine for your project, it is crucial to first understand your specific project needs. Consider factors such as the scale of your work, the types of materials you intend to mix, and the required consistency of the end product. If your project involves smaller tasks like home repairs or landscaping, a portable and compact mixer may suffice. Conversely, larger construction projects might demand a more robust machine capable of handling higher volumes of concrete efficiently.

Additionally, the environment in which you will operate the mixer plays a significant role in your decision-making process. Outdoor projects may require machines with weather-resistant features, while indoor tasks could benefit from quieter models to avoid disturbing the surrounding area.

Understanding these aspects will not only ensure that you choose a mixer that fits your project but will also enhance the overall efficiency and quality of your work. It’s important to approach your selection by considering both the practical applications and your long-term goals for the project, forming a foundation for a successful outcome.

When it comes to selecting a cement mixer for your construction project, understanding the differences between drum and vertical models is crucial. Drum mixers are perhaps the most common choice, designed with a bucket-like shape that rotates to mix the cement thoroughly. This type typically offers a larger capacity, making it ideal for big projects where a substantial volume of concrete is needed. The rotating drum not only ensures uniform mixing but also allows for easy pouring, often equipped with a chute for convenience. However, drum mixers can be bulky and may require more space on-site.

On the other hand, vertical cement mixers are becoming increasingly popular for their efficiency and compact design. These models mix cement using a vertical axis, which allows them to occupy less space, making them suitable for smaller projects or tight job sites. Vertical mixers often provide better mixing results in a shorter time, making them a smart choice when speed is a priority. Additionally, they are generally easier to clean and maintain, as their design minimizes the hassle of leftover material stuck inside the drum. As you evaluate which type of cement mixer is right for your needs, consider the scale of your project, available space, and mixing requirements to make an informed decision.

| Type | Capacity (Cubic Feet) | Power Source | Weight (lbs) | Ideal Use |

|---|---|---|---|---|

| Drum Mixer | 3.5 | Electric | 165 | Small to Medium Projects |

| Vertical Mixer | 4.5 | Gasoline | 200 | Medium to Large Projects |

| Drum Mixer | 6.0 | Electric | 310 | Large Projects |

| Vertical Mixer | 5.0 | Electric | 250 | Medium Projects |

When selecting a cement mixer machine, the capacity of the mixer plays a crucial role in ensuring the success of your project. Mixer capacity is typically measured in cubic feet or liters, and it’s essential to match this to the scale of your undertaking. For small DIY projects or residential tasks such as repairing sidewalks or building patios, a smaller mixer with a capacity of 3 to 5 cubic feet may suffice. This size allows for easy handling and transport while mixing enough material for such minor jobs.

Conversely, larger projects such as commercial constructions, foundations, or extensive landscaping may require a more substantial mixer—ranging from 6 to 12 cubic feet or more. Using a mixer that is too small can lead to productivity losses, as it necessitates more batches to complete the job. Additionally, overloading a smaller unit can damage the machine and compromise the quality of the mix. Therefore, evaluating the volume of concrete needed based on project dimensions will guide you toward the right mixer capacity, ensuring you have the appropriate resources to execute your work efficiently and effectively.

When it comes to choosing a cement mixer machine, one of the critical decisions is whether to go for an electric mixer or a gasoline-powered one. Each power source comes with its own set of advantages and considerations that can significantly impact your project's efficiency and outcome. Electric cement mixers are known for their ease of use and lower noise levels, making them ideal for indoor projects or residential settings where noise could be a concern. They typically require less maintenance than gasoline models, and their electric motors provide consistent power, ensuring a uniform mixing process.

On the other hand, gasoline-powered cement mixers offer superior mobility and can operate in locations without electrical access. This makes them suitable for outdoor construction sites or remote areas where setting up electricity can be challenging. They are generally more powerful, allowing for mixing larger batches more quickly, which can be a crucial factor for large-scale projects. However, with this increased power comes added complexity, such as more frequent maintenance and a higher risk of fuel-related issues. Ultimately, the choice between electric and gasoline cement mixers should be guided by the specific needs of your project, including portability, power requirements, and environmental considerations.

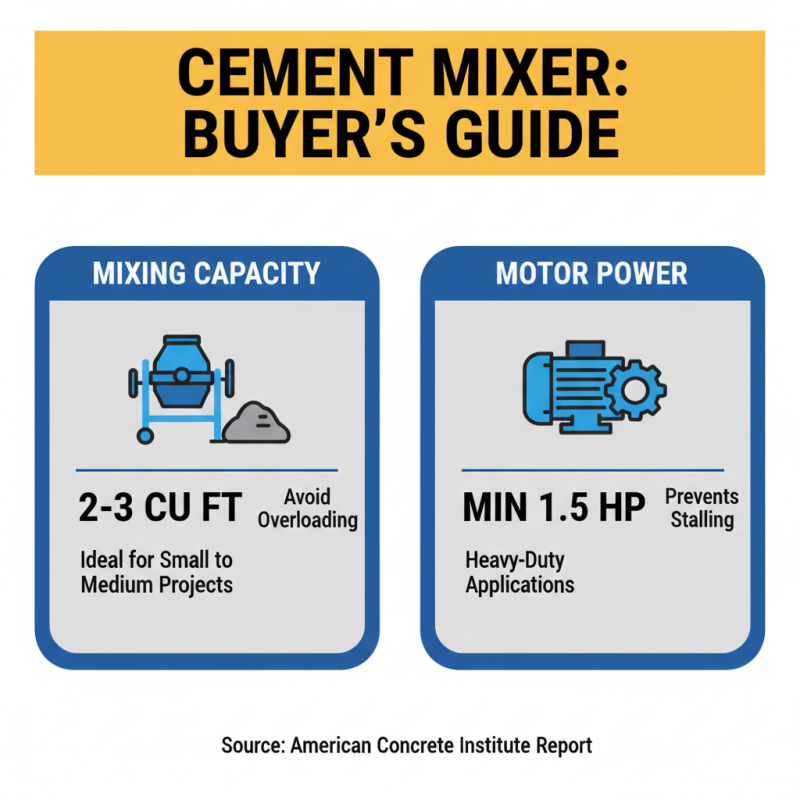

When choosing a cement mixer machine for your project, understanding the key features that contribute to efficient mixing performance is paramount. One crucial specification to consider is the mixing capacity, typically measured in cubic feet or liters. According to a report by the American Concrete Institute, mixers with a capacity of 2 to 3 cubic feet are ideal for small to medium-sized projects, allowing for optimal material blending without the risk of overloading. Additionally, the power of the motor—often indicated in horsepower—is essential, with a minimum of 1.5 HP recommended for heavy-duty applications. This ensures that the mixer can handle dense mixtures without stalling or compromising performance.

Another significant factor is the drum design and its rotational speed. Studies have shown that a drum with a larger diameter and the capability to rotate at different speeds can greatly enhance mixing efficiency. The National Ready Mixed Concrete Association notes that a rotational speed of around 20-30 RPM is most effective for achieving uniform consistency, especially when incorporating additives or aggregates that require thorough mixing. Furthermore, ease of use, durability of materials, and portability are important features that can influence the quality of the mixing process. Considering these specifications will lead to more efficient operations and superior results in your concrete projects.