If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

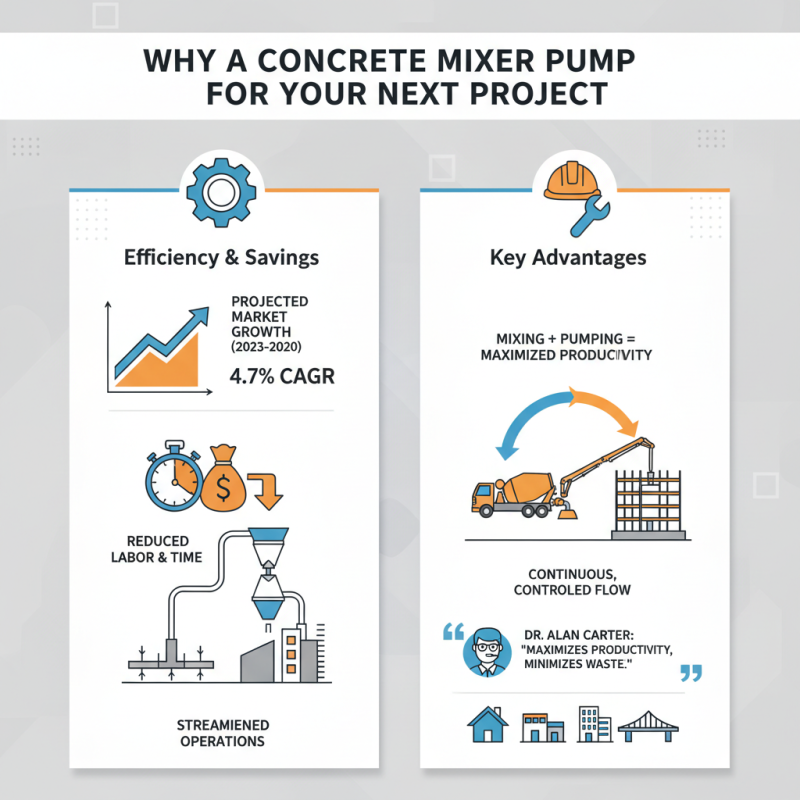

In the ever-evolving landscape of construction technology, the concrete mixer pump has emerged as an essential tool for contractors aiming to enhance efficiency and reduce labor costs. According to a recent market report by Research and Markets, the global concrete mixer pump market is projected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030, indicating a significant shift towards more integrated machinery in various construction projects. This upward trend is attributed to the growing demand for durable and high-quality concrete applications in both residential and commercial sectors.

Industry expert Dr. Alan Carter, a leading figure in construction innovation, emphasizes the practicality of adopting concrete mixer pumps, stating, "The integration of mixing and pumping not only maximizes productivity but also minimizes material waste on site." By leveraging the advantages of concrete mixer pumps, construction professionals can streamline their operations, ensuring a continuous and controlled flow of concrete to meet project timelines effectively. With advancements in technology, these machines are designed to handle a variety of concrete mixtures, making them versatile tools for modern construction challenges. As we delve deeper into the benefits and applications of concrete mixer pumps, it becomes clear why they should be a primary consideration for your next construction project.

Using a concrete mixer pump in construction projects offers several compelling benefits that can enhance efficiency and reduce costs. One of the main advantages is the combination of two essential processes: mixing and pumping. This dual functionality allows for a continuous flow of concrete, eliminating the need for separate equipment and minimizing downtime. As a result, crews can complete tasks more quickly and maintain a steady workflow throughout the project.

In addition to efficiency, concrete mixer pumps also improve precision in placing concrete. These machines can reach difficult areas that standard trucks might struggle with, ensuring that every part of the site receives the exact amount of concrete needed. This capability not only reduces wastage but also enhances the overall quality of the construction work. Furthermore, using a mixer pump reduces the labor required on-site, allowing teams to allocate their resources more effectively and focus on other critical aspects of the project.

This chart illustrates the various benefits of using a concrete mixer pump in construction projects. The metrics such as efficiency, cost-effectiveness, flexibility, ease of use, and labor reduction are illustrated with their respective ratings, showcasing why this equipment is advantageous for modern construction needs.

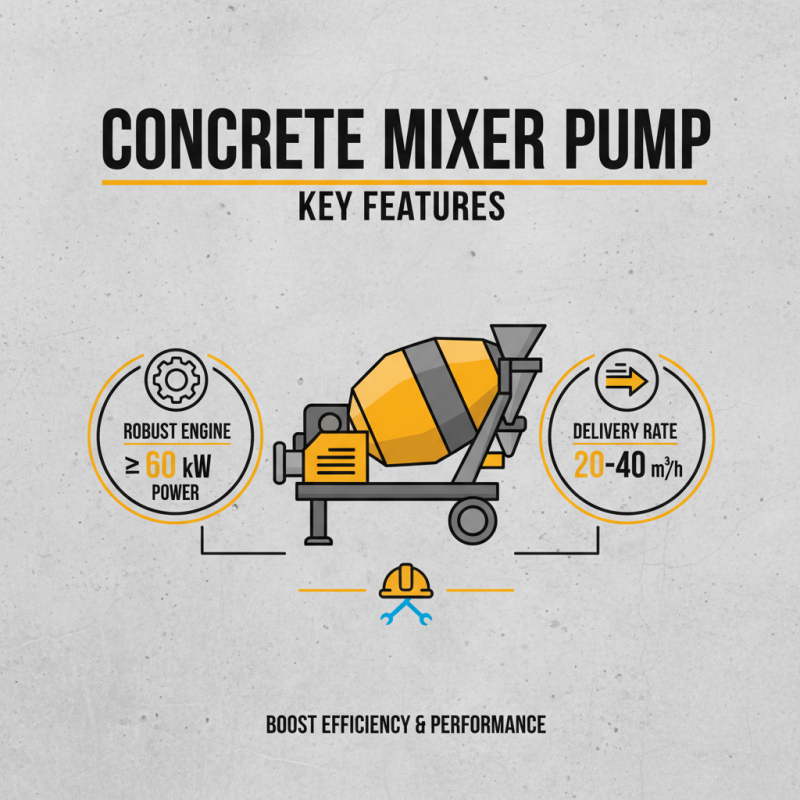

When considering a concrete mixer pump for your next construction project, it's essential to focus on its key features that can significantly impact efficiency and performance. A reliable concrete mixer pump should have a robust engine with a power output of at least 60kW, ensuring adequate performance for various project scales. Additionally, look for pumps with a delivery rate ranging from 20 to 40 cubic meters per hour, as this will enhance productivity on-site, allowing for quicker project completion.

**Tips:** Always evaluate the pump's hydraulic system; a well-engineered hydraulic setup minimizes maintenance needs and provides better control over concrete flow, which is crucial for intricate projects. Furthermore, check for features like automatic feeding systems and remote control options, as these can dramatically boost operational convenience.

Moreover, portability is a vital aspect to consider. Many models are equipped with axle-mounted designs, making them easy to transport between job sites. Also, ensure the pump has high wear-resistant components, as this will prolong the machine's lifespan and reduce overall costs. According to recent industry reports, investing in a high-quality concrete mixer pump can lead to a 25% decrease in manual labor costs, showcasing the significant return on investment these machines offer.

Concrete mixer pumps have become essential tools in construction, offering efficient mixing and transportation of concrete. There are various types of concrete mixer pumps, each tailored for specific applications. For example, trailer-mounted concrete mixer pumps are ideal for smaller projects, providing mobility and versatility for tasks such as residential building or landscaping. Their compact design allows for easy maneuverability in tight spaces, making them an excellent choice for urban sites with limited access.

On the other hand, truck-mounted concrete mixer pumps are designed for larger scale operations. These pumps have a higher capacity and can deliver concrete over greater distances, making them suitable for extensive commercial projects, road construction, and larger infrastructure developments. Their combination of pump and mixer in one unit increases efficiency by reducing the need for additional transport vehicles. Additionally, there are specialized concrete mixer pumps designed for specific applications, such as high-rise buildings, where vertical reach is paramount, or for shotcrete applications in tunneling projects. Each type serves unique needs, illustrating the diversity and adaptability of concrete mixer pumps in modern construction.

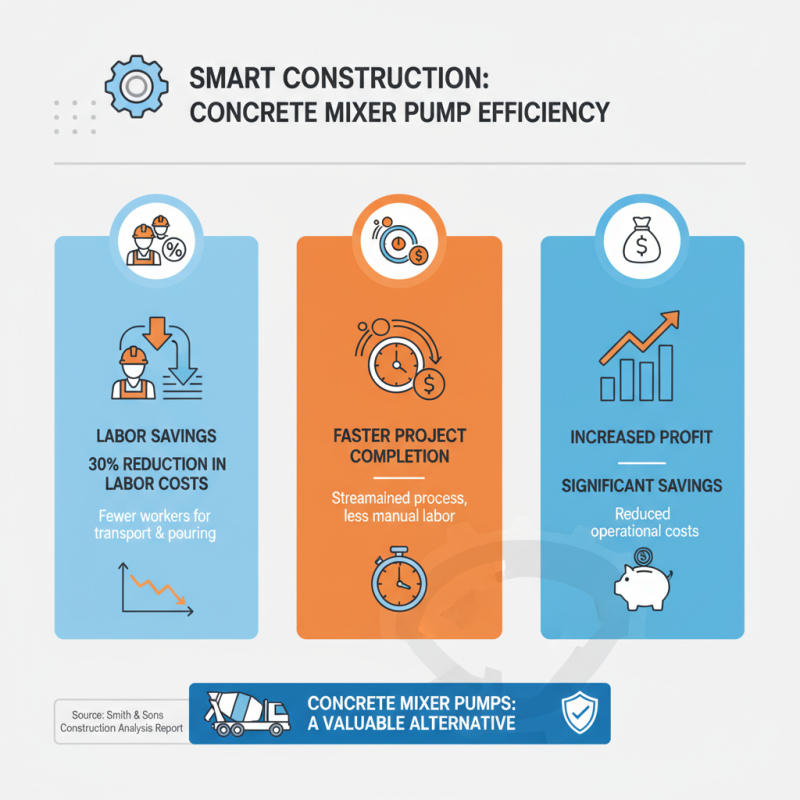

In the construction industry, cost-effectiveness is crucial for project success, and concrete mixer pumps are proving to be a valuable alternative to traditional methods. A report by Smith and Sons Construction Analysis indicates that employing a concrete mixer pump can reduce labor costs by approximately 30%, as fewer workers are needed to transport and pour concrete on-site. This efficiency not only streamlines the construction process but also allows for significant savings in both time and resources.

Furthermore, the use of concrete mixer pumps can lead to enhanced material efficiency. According to a study by Campbell Research, projects utilizing these pumps reported a reduction in waste material by up to 20%. This is largely attributed to the precise control over the volume of concrete poured, minimizing spillage and ensuring that materials are used optimally. In an industry where every dollar counts, these advancements demonstrate how concrete mixer pumps can offer superior economic benefits compared to conventional concrete delivery methods, making them a strong consideration for future projects.

Maintaining a concrete mixer pump is essential for ensuring its optimal performance on any construction project. Regular inspection of the equipment is crucial; operators should check for wear and tear on hoses, seals, and the pump’s motor. A worn-out seal can lead to leaks, which not only affects the mixer’s efficiency but can also create safety hazards on-site. Additionally, keeping the hydraulic fluid at the proper level protects the pump from overheating and premature failure.

Another key maintenance tip involves cleaning the machine after each use. Residue buildup can lead to clogs and operational inefficiencies. Use water to rinse the mixer drum and pump components, ensuring that no concrete is left to harden inside. Regularly lubricating moving parts reduces friction and wear, extending the lifespan of the mixer pump. By following these maintenance best practices, operators can keep their concrete mixer pumps in peak condition, enhancing overall productivity and project outcomes.

| Maintenance Aspect | Recommended Action | Frequency | Importance Level |

|---|---|---|---|

| Oil Levels | Check and refill as needed | Weekly | High |

| Hoses and Fittings | Inspect for wear or leaks | Monthly | High |

| Mixer Drum | Clean after each use | Daily | High |

| Filters | Replace as per manufacturer's guidelines | Every 3 months | Medium |

| Electrical Connections | Inspect for corrosion | Monthly | Medium |

| Pump Components | Lubricate and check for damage | Monthly | High |