If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

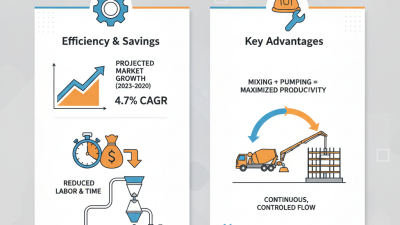

Choosing the right mixer truck is crucial for the success of your construction projects. As an essential piece of equipment in the construction industry, a mixer truck ensures that concrete is mixed on-site and delivered fresh, meeting the specific requirements of each project. With numerous options available on the market, understanding the various types of mixer trucks and their functionalities can significantly impact the efficiency and cost-effectiveness of your operations.

When selecting a mixer truck, several factors come into play, including the capacity of the truck, the types of materials it can handle, and its operational efficiency. It's important to assess the size and scope of your construction projects to determine the appropriate specifications for your mixer truck. Moreover, considering the terrain and accessibility of the job site can help you choose a truck that navigates effectively in various conditions.

Ultimately, a well-chosen mixer truck can enhance productivity, reduce downtime, and contribute to the overall quality of your construction work. By carefully evaluating your project needs and the available mixer truck options, you can make an informed decision that supports your construction goals and ensures successful outcomes.

When selecting a mixer truck for your construction projects, you should consider several key factors that directly impact efficiency and cost-effectiveness. First, evaluate the capacity of the mixer truck based on the scale of your projects. Trucks come in various sizes, and choosing one that matches your workload is essential to prevent delays and optimize materials. A larger capacity may be beneficial for bigger projects, while smaller jobs may require less bulk, ensuring cost savings on transportation.

Another crucial factor is the type of concrete you will be mixing. Different projects may demand specific mixes, including standard concrete, high-strength solutions, or special formulations with additives. The mixer truck's design and features should cater to these requirements to ensure a consistent and quality mix. Additionally, consider the terrain and accessibility of your project site. Trucks with good maneuverability and those that can handle rough or tight spaces will minimize logistical challenges and improve delivery times.

This bar chart represents the key factors to consider when selecting a mixer truck for construction projects, along with their importance ratings based on industry surveys.

When selecting the right mixer truck for construction projects, it’s essential to understand the various types available and their specific applications.

One common type is the standard concrete mixer truck, which features a revolving drum to combine cement, water, and aggregates.

This type is ideal for general construction projects, where a consistent and reliable supply of mixed concrete is required on-site.

Its capacity typically ranges from 6 to 16 cubic yards, making it suitable for both small and large-scale jobs.

Another option is the volumetric mixer truck, which offers the flexibility of mixing concrete on-site.

This type of mixer is equipped with separate compartments for the ingredients, allowing for precise measurements and adjustments based on project needs.

Volumetric mixers are particularly advantageous for projects with varying concrete demands or where the required mix design may change frequently.

Additionally, for specialized applications, such as in the construction of bridges or high-rise buildings, there are also trucks that can handle special mix designs, such as self-consolidating concrete or high-strength concrete, ensuring that project specifications are met with high accuracy and efficiency.

When choosing the right mixer truck for your construction projects, it's essential to evaluate the capacity requirements specific to your construction site. According to a report from the National Ready Mixed Concrete Association, the average construction project requires approximately 70 cubic yards of concrete, although this can vary significantly based on the project's scale. Understanding the volume of concrete needed helps in determining the appropriate mixer truck size, which typically ranges from 6 to 12 cubic yards for a standard mixer.

In addition to volume, the speed of delivery is another critical factor. A study by the American Concrete Institute highlights that timely concrete delivery can impact a project's overall efficiency and cost-effectiveness. Mixer trucks with larger capacities often enable quicker delivery times, thereby minimizing the risk of delays in construction schedules. When assessing capacity, it's also important to consider the site constraints, such as access roads and the space available for maneuvering larger mixer trucks. By carefully evaluating these aspects, construction managers can select a mixer truck that not only meets the volume needs but also complements the specific logistical requirements of their site.

When selecting a mixer truck for your construction projects, understanding the features and technology available is crucial. Modern mixer trucks come equipped with advanced technologies such as telematics systems that provide real-time data on vehicle performance and maintenance needs. According to a recent industry report, incorporating these technologies can reduce operational costs by up to 15%, making it a wise investment for construction companies. Features such as high-strength drums and automated batching systems not only enhance mixing efficiency but also ensure consistent concrete quality, which is critical for structural integrity.

Tips for choosing the right mixer truck include assessing the capacity and drum size based on your project requirements. Larger projects may benefit from trucks with higher cubic yard capacities, which can deliver more concrete per trip, reducing overall transportation time. Additionally, consider the terrain and working conditions of your site; mixer trucks with enhanced off-road capabilities can significantly improve efficiency in challenging environments.

Another key aspect is the environmental impact of your equipment. Many newer mixer trucks are designed with fuel-efficient engines that comply with stringent emissions standards, thus minimizing your project's carbon footprint. Investing in eco-friendly technologies not only aligns with sustainability goals but may also qualify your business for potential tax incentives or grants aimed at promoting greener construction practices.

When planning to purchase or rent a mixer truck for your construction projects, effective budgeting is crucial. Begin by assessing the total costs associated with both options. For purchasing a mixer truck, consider the initial cost, insurance, maintenance, and depreciation over time. If you choose to rent, factor in rental fees, insurance costs, and any additional charges such as fuel and maintenance. Understanding these expenses will help you make a well-informed decision that aligns with your financial capacity.

Additionally, think about the project duration and frequency of use. If you have a short-term project or don’t anticipate frequent use, renting may be the better financial choice. Conversely, if you expect to utilize the mixer truck consistently over several projects, investing in a purchase could offer long-term savings. Take into account the potential resale value of the truck as well. Each choice has its pros and cons, so weigh them carefully against your budget and project requirements to ensure you choose the most economical option.