If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

Choosing the right industrial concrete mixer for your projects is crucial. The global concrete mixer market was valued at approximately $6.5 billion in 2020, highlighting its importance in construction. This market is expected to grow by 6.5% annually. Selecting the correct mixer can significantly impact productivity and project costs.

An industrial concrete mixer must meet various criteria. These include size, capacity, and mixing speed. A survey of construction firms showed that 70% prioritize efficiency in their equipment. However, many still face challenges in making the best choice. Misunderstandings about mixer specifications often lead to poor purchasing decisions.

Not all mixers are suitable for every job. Some projects require high-capacity mixers, while others can work with smaller models. Decisions should be based on specific project needs. Failure to do so may result in delays and increased costs. Understand your requirements before investing. This approach will ensure the right mixer enhances your project's success.

When selecting an industrial concrete mixer, understanding the different types available is crucial. There are drum mixers, pan mixers, and twin-shaft mixers. Each type serves distinct needs. Drum mixers are commonly used for smaller jobs. They offer a straightforward design, ideal for projects with less demanding requirements. However, their mixing efficiency can sometimes be subpar.

Pan mixers, on the other hand, are known for their rapid mixing capabilities. They are perfect for projects requiring high-quality concrete. Yet, their cost can be daunting for smaller enterprises. Twin-shaft mixers provide consistent results, ideal for large-scale projects. The downside? They can consume more power and may be cumbersome to maintain.

Every project has unique demands. A mixer that works well for one may not suit another. Reflecting on your specific needs is vital. Consider how often you will use the mixer and the volume of concrete required. Balancing cost, efficiency, and required output will lead to better choices.

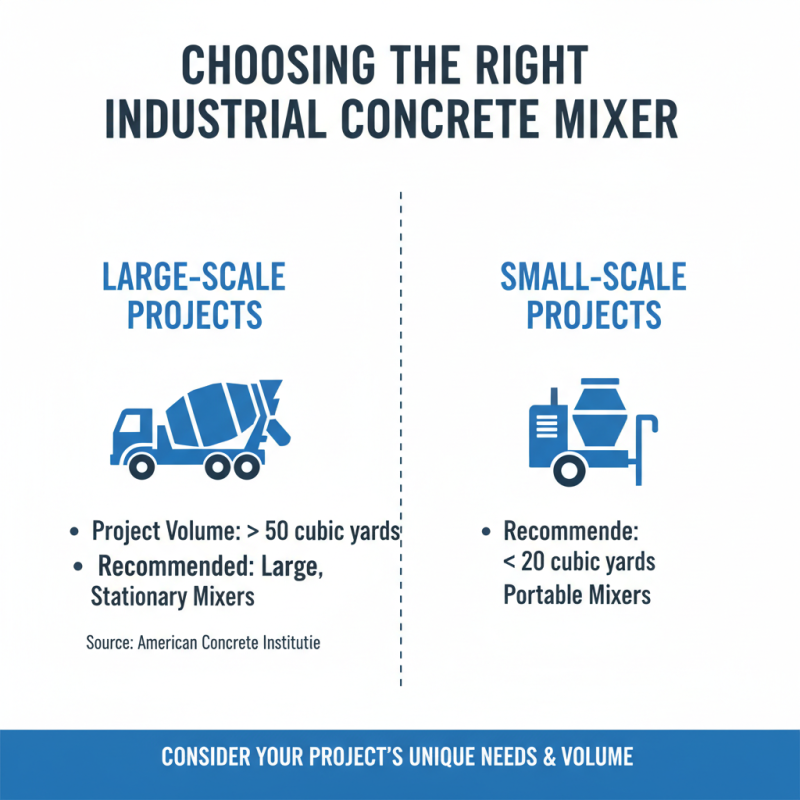

Choosing the right industrial concrete mixer requires careful consideration of your project’s unique needs and volume requirements. Assessing these needs starts with understanding the scale of your projects. Data from the American Concrete Institute indicates that projects with volumes exceeding 50 cubic yards typically benefit from larger mixers. Smaller projects, on the other hand, may only require portable options that handle up to 20 cubic yards efficiently.

Concrete mixtures vary not only in volume but also in type. For instance, if your project requires specialized mixes, such as high-strength or self-consolidating concrete, ensure that the mixer you choose can accommodate these specifications. It's essential to analyze your concrete formulation and transport needs as well.

Tips: Always consider the mixer’s ease of cleaning and maintenance. A more complex mixer may save time initially, but can lead to frustrating downtime if not maintained properly. Additionally, take note of energy efficiency. A mixer that consumes less power can lead to significant savings over time. Evaluate the mixer’s performance under various conditions to ensure reliability. Not all mixers will perform equally in fluctuating climate or workload situations.

Choosing the right industrial concrete mixer can seem overwhelming. However, focusing on key features simplifies the process. One essential aspect is the mixer’s capacity. Different projects require varying amounts of concrete. A small mixer is great for minor tasks, while larger jobs demand larger capacities. Always calculate your project needs carefully.

Another important feature is the power source. Mixers can be electric or diesel-powered. Electric mixers are quieter and cleaner but may struggle with heavy loads. Diesel models can handle more substantial projects but produce more noise and emissions. Balance these factors according to your project environment.

Lastly, consider the mixer’s durability. Look for sturdy materials that withstand heavy use. Some mixers may seem lightweight, but they could break under pressure. Pay attention to design and warranty options as well. Understanding these details is crucial for making a smart investment.

When choosing an industrial concrete mixer, budget is a significant factor. According to a recent industry report, 35% of project managers cite cost as a leading constraint. It's essential to evaluate both initial costs and long-term expenses. High-quality mixers can seem pricey upfront but often last longer, leading to lower maintenance costs. Conversely, cheaper options may require frequent repairs and replacement.

Moreover, consider the mixer’s efficiency. A well-designed mixer can optimize material use and reduce waste. The American Concrete Institute reports that effective mixing can decrease material costs by up to 15%. This savings can influence overall project viability.

It's also crucial to think about your project scope. A smaller operation may not require a large capacity mixer, potentially leading to waste and higher costs. Similarly, overestimating your needs can drown your budget in unnecessary spending. Reflect on past projects. Analyze what worked and what didn't. Understanding your specific needs and cost limitations can significantly enhance your project execution.

When considering industrial concrete mixers, maintenance and durability play crucial roles. Regular upkeep extends the lifespan of your equipment. According to industry reports, nearly 30% of mixer failures are due to inadequate maintenance. Simple tasks, like cleaning and lubrication, can prevent costly breakdowns.

Wear and tear on components is inevitable. Paying attention to the mixing blades is vital. They often face high stress and wear out more quickly. Scheduling inspections every 200 hours of operation can help catch issues early. Operators can save money by addressing small problems before they escalate.

Choosing mixers made of durable materials is essential for long-term use. Steel and other high-strength alloys can resist the harsh conditions found on job sites. However, remember that even the best materials can fail without care. Keep a maintenance log to track repairs and replacements. This approach enables better planning for upcoming projects. Failure to do so may lead to unexpected downtime.