If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

Choosing the right volumetric mixer truck is crucial for construction projects. This decision directly impacts efficiency and material quality. According to a report by the National Ready Mixed Concrete Association (NRMCA), construction projects can see up to a 30% increase in productivity with the proper equipment.

Experts in the field emphasize the importance of understanding your project needs. John Smith, a leading expert in concrete technology, states, "Selecting the right volumetric mixer truck can significantly change the project's success." His insights reflect the importance of choosing a mixer that fits specific requirements. Factors like capacity, mobility, and mixing technology must be considered.

Many in the industry overlook key details when selecting equipment. Some may prioritize cost over quality, leading to issues later. An inadequate mixer can result in inconsistent mixes. This can jeopardize project integrity and lead to costly repairs. We must reflect on our choices in equipment selection to ensure long-term success.

Volumetric mixer trucks are essential for modern construction projects. These vehicles mix concrete on-site, ensuring fresh material. According to the National Ready Mixed Concrete Association (NRMCA), these trucks can improve productivity by 30% compared to traditional mixing methods. Contractors can accurately control the volume of concrete needed, reducing waste.

Understanding the functionality of volumetric mixers is key. They consist of separate compartments for aggregates, water, and cement. This allows for real-time mixing according to project specifications. A study by the Portland Cement Association highlights that volumetric mixers can help maintain desired strength and consistency. However, operators may face challenges in calibration and delivery timing.

Proper training is crucial. The complexity of settings can vary. A miscalculation or equipment malfunction during high-demand periods can lead to delays. Focusing on maintenance routines also helps avoid operational issues. Ultimately, understanding both the benefits and limitations of volumetric mixers ensures better decision-making for construction needs.

| Feature | Description | Considerations |

|---|---|---|

| Capacity | The amount of concrete the mixer can carry in one load, typically measured in cubic yards or cubic meters. | Choose based on the size of the projects and the volume of concrete needed. |

| Mixing Technology | Different mixers use various technologies to mix concrete, affecting consistency and speed. | Evaluate the quality of the mix and the mixing time required for your projects. |

| Mobility | The truck's ability to move quickly between job sites. | Consider the terrain and distance to project sites. |

| Ease of Use | How user-friendly the controls and functions are for operators. | Look for features that facilitate quick learning for new operators. |

| Maintenance | Ease of servicing and availability of spare parts. | Consider budget for maintenance and availability of service personnel. |

| Cost | Initial purchase price, as well as operating costs. | Ensure the investment aligns with long-term financial goals. |

Selecting the right volumetric mixer truck requires careful consideration of your project's specific needs. Each construction site has unique requirements. Analyze your project's size and the volume of materials needed. If you're working on a small residential project, a smaller mixer may suffice. Larger commercial sites may need a high-capacity mixer for efficiency.

Evaluate the materials you'll be mixing. Different trucks excel in mixing concrete, mortar, or other materials. Think about your workflow. Will the site have access issues? Maneuverability is key in tight spaces. Consider your timeline too. Some mixers can deliver materials faster than others.

Don’t overlook the operator's expertise. A skilled operator can maximize the mixer’s capabilities. Yet, if the operator lacks experience, the project could face delays. Reflect on your budget as well. Sometimes the cheapest option may lead to cost overruns due to inefficiencies. Make thoughtful choices based on your specific needs and constraints.

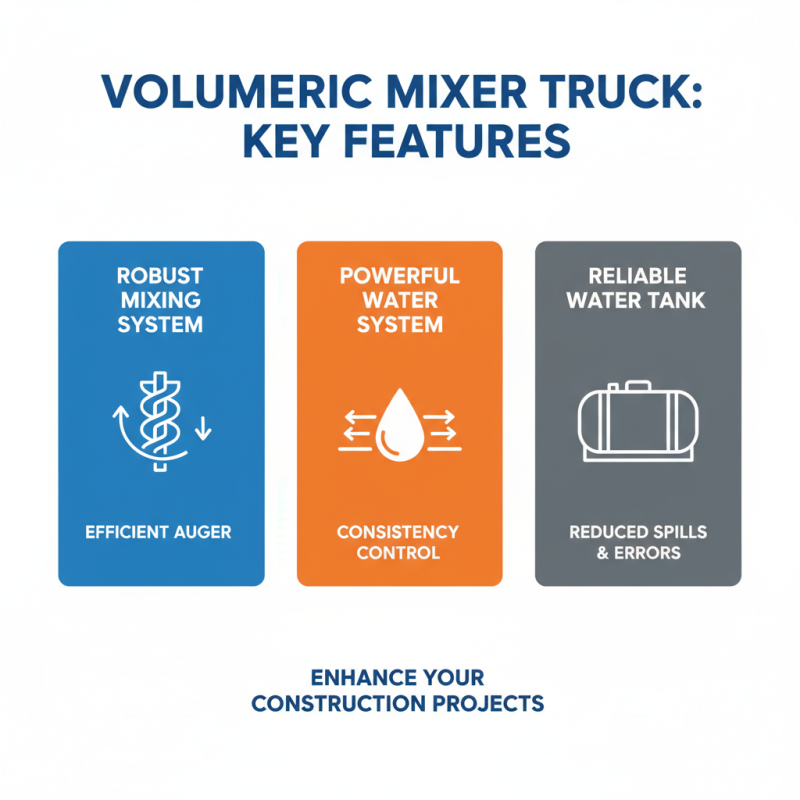

When choosing a volumetric mixer truck, consider critical features that can enhance your construction projects. A robust mixing system is essential. Look for a truck with an efficient auger that evenly blends materials. A powerful water system is also important. This feature helps control the mix's consistency. A reliable water tank reduces spills and errors.

Another significant aspect is the control system. Ensure it is user-friendly, as this will save time. Some trucks offer touchscreen controls, making operations easier. LED displays can provide real-time information about the mixing process. Pay attention to the truck's size and capacity as well. A larger truck may help with higher volume projects but could be cumbersome in tight spaces.

Additionally, think about maintenance needs. Trucks that are easy to clean and require less downtime will be more efficient. Evaluate the durability of materials used in the truck’s design. Ask yourself: will it withstand harsh working conditions? Each feature contributes to overall performance. It’s vital to prioritize the attributes that align with your specific project requirements.

When choosing a volumetric mixer truck, cost is a critical factor. The price of these trucks can vary significantly. Factors such as capacity, features, and condition affect pricing. Setting a clear budget helps narrow down options. You might find affordable choices, but they may lack essential features.

Consider potential additional costs. Maintenance and repair can add up over time. Fuel efficiency also impacts overall expenses. Will you need financing? Explore various funding options available for your budget. A more expensive truck might save money in the long run with better efficiency and durability.

It’s essential to research and compare your choices. Sometimes, a lower-priced mixer truck seems tempting. But hidden costs could lead to regrets. Think about the longevity and reliability of the truck. Will it meet your long-term construction needs? Make decisions with both immediate costs and future savings in mind. This balance will guide you toward the right choice.

Maintenance and support are critical when choosing a volumetric mixer truck. According to industry studies, regular maintenance can extend the lifespan of these trucks by up to 30%. Ignoring maintenance can lead to costly repairs. Simple tasks, like checking fluid levels and tire pressure, should be routine. Yet, many operators overlook these checks.

Furthermore, support from manufacturers matters. A report by the American Concrete Institute indicates that 70% of operators favor brands that provide comprehensive support. This includes training programs, technical assistance, and access to spare parts. When providers fall short in these areas, it can hinder productivity. Mixer trucks often face wear and tear, which means timely access to replacement components is vital.

Lastly, consider the complexity of parts. Not all trucks use the same components. For example, wear on the auger can negatively impact material quality. Operators often underestimate the effect of small issues. Regular inspections can catch these problems before they escalate. Inadequate attention could result in downtime, affecting project timelines and profitability. Investing in maintenance is not just wise—it's essential.