If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

In the ever-evolving landscape of construction, the choice of materials and equipment plays a pivotal role in ensuring efficiency and quality. One tool that has gained prominence among construction professionals is the volumetric concrete lorry. This innovative vehicle offers a unique solution to the challenges of on-site concrete mixing, providing a level of flexibility and precision that traditional methods often lack. As construction projects become more complex and time-sensitive, the ability to produce fresh concrete on demand is invaluable.

Utilizing a volumetric concrete lorry not only streamlines the mixing process, but it also reduces waste and enhances sustainability. With the ability to measure and mix concrete to the exact specifications needed at any given moment, contractors can minimize excess material that typically results from pre-mixed deliveries. This capability allows for greater control over the project timeline and costs, making volumetric concrete lorries an attractive option for both large-scale developments and smaller renovation tasks.

Choosing a volumetric concrete lorry for your next construction project can transform your approach to concrete work, ensuring that you are equipped to meet both the challenges and demands of modern building endeavors. Embracing this technology not only signifies a commitment to efficiency and quality but also a step towards more innovative and sustainable construction practices.

Volumetric concrete lorries offer a multitude of benefits that can streamline the construction process and enhance overall project efficiency. One of the primary advantages is their ability to mix concrete on-site, ensuring that the mix is fresh and tailored to the specific requirements of the project. This not only minimizes waste but also allows for precise control over the concrete's composition, ensuring optimal strength and durability while meeting varying project demands.

Another significant benefit is the flexibility that volumetric concrete lorries provide. Construction projects often face unpredictable variables, such as weather changes or shifts in scheduling. With volumetric lorries, contractors can easily adjust the amount of concrete being mixed and delivered according to real-time needs, eliminating the risk of over-ordering or running short. This adaptability can lead to significant cost savings and improved project timelines, making it a practical choice for contractors looking to enhance their operations.

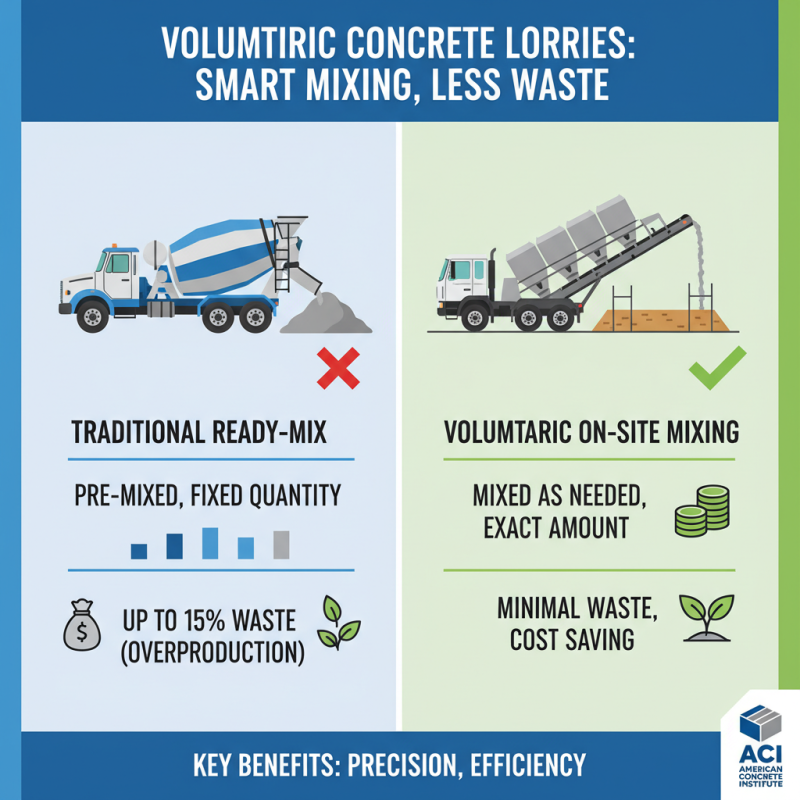

Volumetric concrete lorries are revolutionizing the way concrete is mixed and delivered in the construction industry. Unlike traditional ready-mix trucks, volumetric lorries allow for precise on-site mixing, which ensures that the concrete meets the exact specifications needed for each project. According to a report by the American Concrete Institute, up to 15% of concrete in traditional deliveries is wasted due to overproduction, which often leads to increased costs and environmental concerns. By using volumetric technology, concrete is only mixed as needed, dramatically reducing waste and ensuring optimal material usage.

Furthermore, these lorries are equipped with advanced technology that monitors the mixing process, allowing for real-time adjustments to the concrete's composition. Research from the National Ready Mixed Concrete Association shows that 98% of contractors prefer volumetric mixers for projects requiring specific mixtures, such as those with varying strengths or additives. This ability to customize mixtures on-site not only enhances the quality of the concrete but also minimizes delays caused by waiting for the right batch to arrive. Overall, the accuracy and efficiency offered by volumetric concrete lorries make them an essential choice for any modern construction project.

Choosing volumetric concrete for your construction project presents a cost-effective solution that can lead to significant savings. Unlike traditional concrete deliveries, volumetric lorries enable you to mix the exact amount of concrete needed on-site. This on-demand mixing reduces waste typically associated with surplus concrete and minimizes the financial loss from unused materials, a common issue with pre-mixed concrete deliveries.

Additionally, the flexibility offered by volumetric concrete lorries allows you to adjust the mix design according to project specifications. This adaptability can lead to better material usage and optimized structural performance, thereby enhancing the overall efficiency of the project. With no waiting times for concrete to arrive and the ability to produce multiple mixes throughout the day, contractors can streamline their workflows, reducing labor costs and minimizing downtime. Overall, investing in volumetric concrete not only optimizes material expenditure but also increases project efficiency, making it a smart choice for any construction endeavor.

Volumetric concrete lorries offer unparalleled flexibility and customization for modern construction projects. Unlike traditional ready-mix concrete suppliers, these lorries allow contractors to mix the exact amount of concrete needed on-site, significantly reducing waste and ensuring the right specifications for each unique job. This adaptability means that construction teams can respond to changes in project requirements swiftly, adjusting mix designs and quantities without the constraints imposed by pre-mixed delivery schedules.

Moreover, volumetric lorries can carry multiple types of concrete mixes simultaneously, enabling a variety of applications within a single project. This capability empowers contractors to handle various aspects of construction—from foundation work to decorative elements—without the need for multiple deliveries. By eliminating the risk of running out of material midway through a pour, these vehicles enhance efficiency and project timelines, ultimately leading to a smoother workflow and reduced overall costs. The precision and convenience provided by volumetric concrete lorries are invaluable for any construction endeavor that values flexibility and tailored solutions.

The use of volumetric concrete delivery systems offers significant environmental benefits that are becoming increasingly important in today's construction landscape. One of the primary advantages lies in the reduction of waste generated during the pouring process. According to industry reports, volumetric mixers allow for precise measurement of materials, producing only the exact amount of concrete needed for a project. This can lead to a reduction in concrete waste by up to 30%, thereby minimizing the environmental impact associated with surplus materials that would otherwise end up in landfills.

Additionally, the water-to-cement ratio can be adjusted on-site, which not only enhances the quality of concrete but also ensures optimal resource usage. Research from the American Concrete Institute suggests that maintaining an ideal mix can improve the durability and lifespan of concrete structures, potentially reducing the need for future repairs and reconstruction. Furthermore, volumetric concrete delivery systems are often more energy-efficient compared to traditional methods, as they operate using fewer trucks and less fuel. A study indicated that using volumetric mixers can reduce CO2 emissions during the transport of concrete by as much as 15%, contributing to a lower carbon footprint in construction projects.