If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

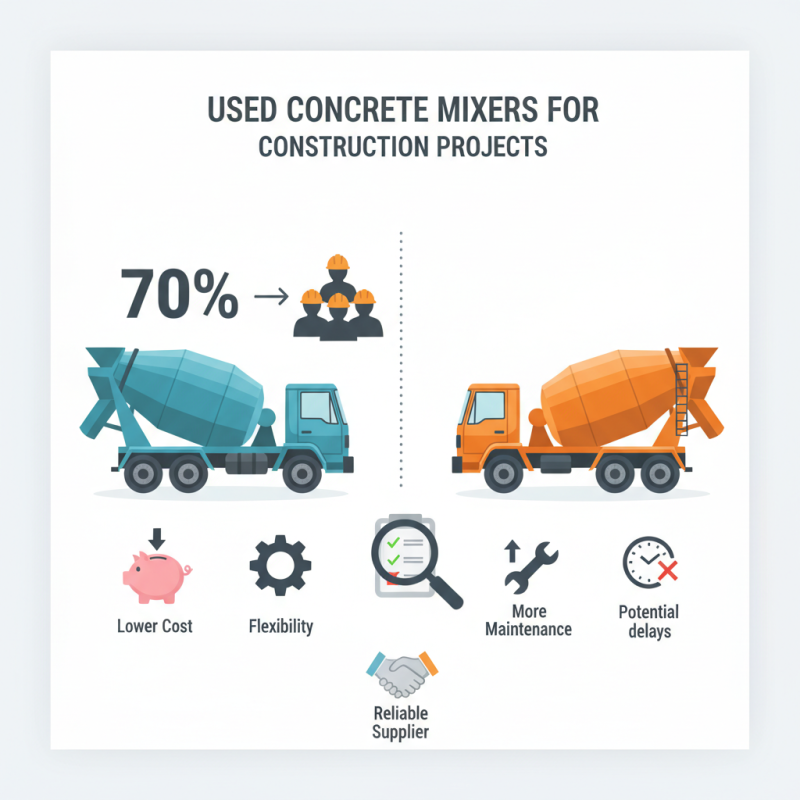

In today's construction industry, the choice between new and used equipment significantly impacts budget and efficiency. A used concrete mixer can be a wise investment for contractors seeking cost-effective solutions. According to the latest report from the Concrete Equipment Association, nearly 70% of construction managers prefer used machinery for project flexibility.

Expert John Smith, a leading figure in the concrete machinery field, states, "Used concrete mixers often provide outstanding value." His insight highlights an important consideration. Cost savings are appealing, but potential risks exist. It’s vital to evaluate the condition and history of a used mixer before purchasing. Many buyers overlook this step, leading to unexpected repairs.

While used concrete mixers can reduce expenses, they may require more maintenance than new models. Contractors should factor this into their decision-making. Inadequate assessments can lead to rushing purchases that affect project timelines. Selecting a reliable supplier becomes crucial. Ultimately, a strategic approach to acquiring a used concrete mixer can ensure both quality and value in construction projects.

When it comes to construction projects, investing in a used concrete mixer can be a smart choice. A report from the American Concrete Institute indicates that the construction industry is projected to grow by 4.5% annually. This means more demand for concrete and the need for efficient equipment. A used mixer can meet these needs without exorbitant costs.

Another advantage is sustainability. The construction sector generates around 40% of the world's carbon emissions. By opting for a used mixer, companies can reduce the need for new manufacturing processes. This helps minimize waste and supports eco-friendly practices. However, it is essential to inspect the equipment thoroughly. Some older mixers may require repairs, which can lead to unexpected expenses.

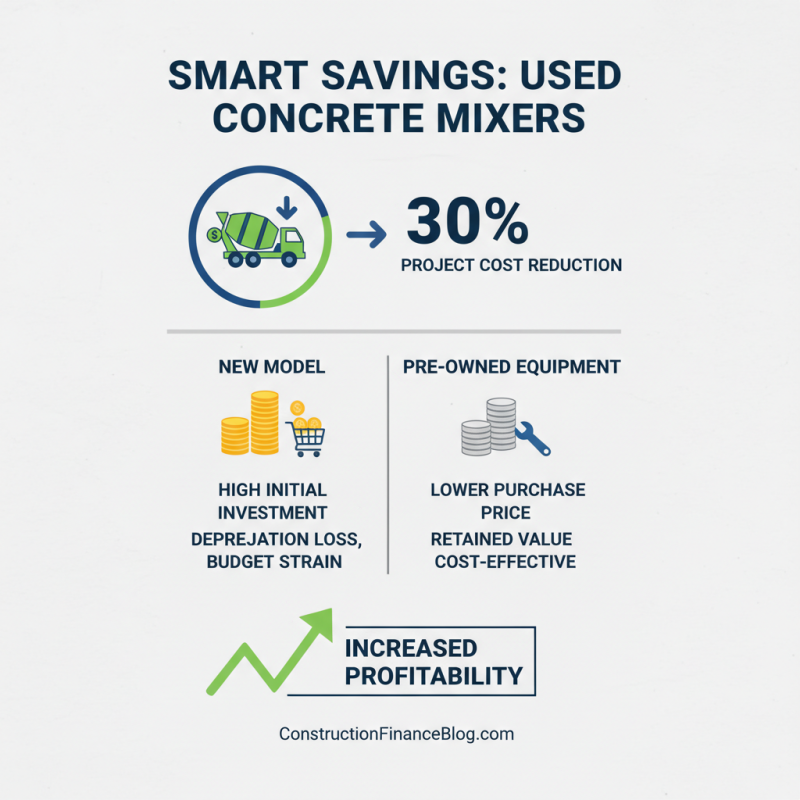

Cost savings are significant. A used concrete mixer can cost up to 30% less than a new one. This can be crucial for smaller contractors and projects operating on tight budgets. It's vital to combine this with an assessment of the mixer’s performance history. Not all used equipment is equally reliable, and some may have hidden defects that require addressing. Balancing savings with quality is a necessary reflection for any construction team.

Choosing a used concrete mixer can significantly reduce project costs. Many construction companies find that purchasing pre-owned equipment saves them up to 30% compared to new models. The construction industry often faces budget constraints. Selecting a reliable used mixer can help manage expenses while maintaining efficiency.

Used mixers often come with a history and may require some maintenance. A thorough inspection is crucial. Data from recent market studies indicates that properly maintained used concrete mixers last about 10-15 years. This longevity can make them a smart investment, despite potential initial imperfections. Buyers should be prepared for minor repairs, as they can arise.

Tips: Always check the mixer’s operational history. Ask for maintenance records. Look for signs of wear and rust. These factors greatly affect the mixer’s future performance. Spending time on research can prevent costly mistakes. Seek expert opinions when evaluating equipment. Your time spent upfront will pay off in the long run.

Used concrete mixers offer remarkable durability and reliability for construction projects. These machines often endure harsh conditions. They are built to last, made from robust materials. Many experienced contractors trust second-hand equipment. A well-maintained mixer can still operate efficiently for years.

Some might worry about the history of a used mixer. Was it well cared for? Did it suffer any major issues? These concerns are valid. Checking the equipment's history is crucial. Look for signs of wear. Inspect the engine, the drum, and the hydraulics. Ask for maintenance records if possible. This diligence can save you from headaches later.

Buying used often means significant savings. The upfront cost is lower compared to new models. However, buyers should consider potential repairs. Sometimes, an older mixer may require parts replacement. Budget for this possibility to avoid surprises. With careful research and thorough inspections, a used concrete mixer can be a sound investment for any construction project.

Choosing a used concrete mixer can greatly reduce waste. By opting for machinery that has already been used, we prevent additional manufacturing costs and resource consumption. This choice contributes to a more sustainable approach in construction. Construction generates waste, and reusing equipment plays a part in minimizing this issue.

Environmental considerations come into play when selecting machinery. It’s important to evaluate the operational efficiency of used mixers. Aging equipment may have wear and tear, leading to higher emissions or energy use. This could diminish the environmental benefits we aim for. Regularly assessing equipment ensures it aligns with sustainability goals.

Opting for used machinery also supports a circular economy. This approach encourages responsible consumption and resource lifecycle management. Yet, potential buyers must scrutinize a mixer’s condition closely. An investment in a used mixer should not overlook the hidden costs of repairs and maintenance that might emerge later.

| Criteria | Considerations | Environmental Impact |

|---|---|---|

| Cost Efficiency | Lower purchase price compared to new mixers | Reduces financial strain on projects |

| Resource Utilization | Reusing machinery reduces demand for new resources | Minimizes industrial waste |

| Carbon Footprint | Less energy consumption in manufacturing new equipment | Helps in reducing overall emissions |

| Durability | Older models may have proven longevity | Encourages long-term use of existing resources |

| Accessibility | Availability of used models in various conditions | Promotes local economies and reduces transport emissions |

When considering a used concrete mixer, maintenance plays a crucial role in its longevity and performance. Regular upkeep can significantly extend the lifespan of the equipment. A 2019 industry report highlighted that proper maintenance can increase a machine’s efficiency by up to 30%. Small actions, like checking fluid levels regularly, can prevent major breakdowns. Keeping the mixer clean is vital; concrete residue can cause wear and tear over time.

It’s essential to inspect the wear parts frequently. The drum may show signs of abrasion after extensive use. According to data from construction equipment specialists, nearly 70% of mechanical failures occur due to neglect in maintenance. Additionally, ensuring the motor's health is pivotal. An overheating motor can lead to catastrophic failures. Implementing a routine maintenance schedule can save time and costs in the long run.

However, even with diligent care, mistakes can happen. Sometimes, operators overlook simple tasks, leading to bigger issues. For instance, using the wrong lubricant can cause gear malfunction. This highlights the need for training and awareness in proper maintenance practices. Emphasizing the importance of these measures is vital for those relying on used concrete mixers.