If you are interested in financing to fund your Bay-Lynx purchase, we recommend that you connect with Easylease Corp., a Canadian-based leasing and finance company that offers premier equipment leasing and financial services. They are focused on making it easier than ever before for companies to overcome cash flow and resource constraints to acquire the assets they need to grow their business.

Leasing through Easylease Corp. can offer several benefits:

Click here for your Canadian instant lease quote >>

For US customers, Click here for your instant lease application >>

A cement mixer is an essential tool for any construction project. It mixes concrete efficiently, ensuring a consistent and strong mixture. Choosing the right model can significantly impact your work.

There are various cement mixer models available in the market. Each has its features and specifications. It's important to consider what you need for your specific job. Some models are portable, while others are larger and more powerful.

When selecting a cement mixer, reflect on factors like size, capacity, and ease of use. You may find some models offer excellent performance but lack user-friendliness. The right choice can save you time and effort on the job site. Prioritize your construction needs wisely to ensure success.

When considering cement mixers, understanding the types available is crucial. There are several basic types: drum mixers, pan mixers, and trench mixers. Each type serves distinct purposes in construction projects. For smaller jobs, drum mixers are often preferred due to their portability. However, they can be less efficient for larger batches. A report from the Construction Industry Institute suggests that choosing the right mixer can impact project timelines by up to 25%.

Pan mixers, known for their efficiency, mix materials well and minimize waste. They are ideal for high-capacity jobs. These mixers are typically used in manufacturing settings. Trench mixers are meant for deep mixing in difficult conditions, often at construction sites or roadworks. However, their complex operation may require skilled operators. A study reported nearly 30% of project delays result from improper equipment usage.

Despite their advantages, each mixer type has limitations. For example, drum mixers come with a slower mixing process. This can affect overall productivity. While pan mixers save materials, they are often bulkier. Understanding these nuances is essential for effective planning. Mastering the right cement mixer type can yield smoother operations and improve outcomes on the job site.

Choosing the right cement mixer for construction projects is crucial. Key features can greatly affect performance. Mixing capacity is essential; it determines the volume of concrete produced per batch. Most mixers provide a capacity range from 2 to 12 cubic feet. Generally, larger projects benefit from bigger mixers, supporting higher output.

Another important factor is power. Electric mixers are convenient for residential work. They are quieter and require less maintenance than gas models. However, gas mixers offer more power for heavy-duty tasks. A report from the Construction Industry Research Board indicates that more than 70% of builders prefer electric mixers for small-scale jobs due to their efficiency.

Also, consider portability. Some mixers are compact and can be easily transported. This feature is great for on-site work. Check the weight and size before making a decision. Tips: Always read customer reviews. Understand what contractors find lacking in a machine. It helps avoid purchasing a model with frequent issues. Keep in mind the mixer’s durability. A less durable model might be cheaper but could incur higher costs in replacements over time.

When choosing a cement mixer for your construction projects, specifications are vital. Different models offer unique features. A good mixer should mix concrete thoroughly and efficiently. Consider the drum capacity. Larger drums can hold more materials but may be harder to maneuver. Smaller models are lighter but may require more batches.

Electric mixers are quieter. They are easy to start and maintain. On the other hand, gas mixers provide more power. They are suitable for larger jobs but can be unpredictable. Pay attention to the mixing speed as well. Faster speeds result in quicker batch times. Yet, some operators may struggle with control.

Wheels are important for mobility. Look for sturdy, reliable wheels that can handle rough surfaces. Stability is also crucial; a wobbly mixer can lead to uneven concrete. Lastly, check the safety features. Mixers should have guards and emergency shut-off options. Always reflect on what fits best for your needs. Not every model will be perfect for every task.

When it comes to choosing a cement mixer, user reviews are invaluable. Many users report that the capacity of the mixer is crucial. Most residential projects need a mixer that can handle at least 3 cubic feet. A recent survey indicated that over 70% of users prefer mixers with this capacity. These mixers balance practicality and efficiency, especially during smaller jobs.

Another important factor is portability. Users often mention the weight and size of the mixer. A lighter mixer can be moved easily on job sites. Some models weigh over 100 pounds, making them challenging to transport. User feedback suggests that mixers under 70 pounds are ideal for residential use.

Durability is another area for reflection. Many users point out that frequent use can wear out mixers quickly. A report from a construction tools analysis group revealed that over 50% of mixers fail within two years due to heavy use. Inspecting for solid construction and quality materials is essential. Users should consider the trade-off between cost and durability carefully.

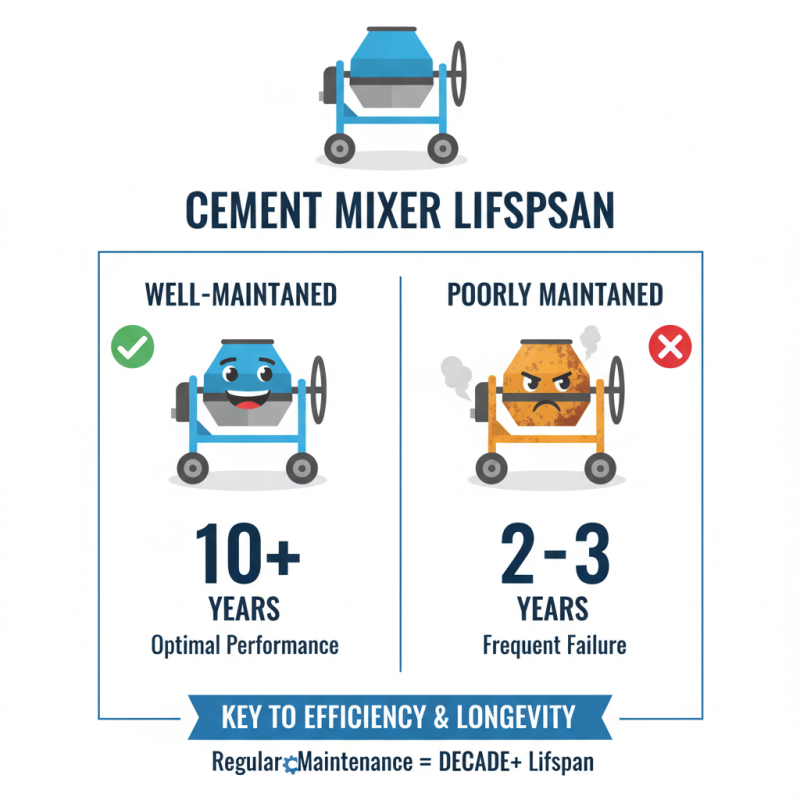

Cement mixers are essential for construction projects. They help create concrete efficiently. Regular maintenance extends their lifespan and ensures optimal performance. According to industry reports, a well-maintained mixer can last over a decade, while poorly cared for mixers may fail within a few years.

One crucial maintenance tip is to clean the drum after each use. Residues can harden, making it difficult for your mixer to operate properly. Water and a stiff brush can work wonders. Additionally, lubricating the moving parts every few months is vital. This practice reduces wear and tear, preventing costly repairs down the line.

Regularly check electrical components, too. Loose wires or damaged plugs can lead to accidents. It's recommended to inspect these parts monthly. Users often overlook this aspect, leading to dangerous situations. Maintaining your mixer requires diligence, but the payoff is significant. Proper care ensures reliable performance, allowing you to focus on your construction needs without unnecessary interruptions.